improve work performance through a combination of visualization, just-in-time value creation, and focus on flow. Kanban is an excellent method to help manage and improve the operations of an agile change initiative.

improve work performance through a combination of visualization, just-in-time value creation, and focus on flow. Kanban is an excellent method to help manage and improve the operations of an agile change initiative. Kanban is a core concept to the Lean Change method. Kanban is used in the following ways:

1. to track and manage both minimum viable changes and improvement experiments on various kanban boards

2. as a means of providing quantifiable validation of improvement experiments and the underlying change during the verify performance stage of the Validated Change Lifecycle.

3. As an alternative change management method that can take over from the method once the organization achieves sufficient maturity to operate in a continuous improvement mindset

Both Minimum Viable Changes and Improvement Experiments Are Managed Visually Using Kanban Systems

A focal premise of the Lean Change method is that Kanban is used to manage the flow of change, taking advantage of visual, just-in-time techniques. The Lean Change method uses various Kanban boards to define and visualize how change progresses through the organization, helping change agents get into a state of change "flow".A Validated Change Kanban is used to track individual Minimum Viable Changes as they pass through the Validated Change Lifecycle. This allows teams of change agents to coordinate and collaborate during a change initiative, taking advantage of Kanban features such as visualization, explicit policies, standups, and limiting the amount of change in progress.

An Improvement Experiment Kanban is used to track Improvement Experiments for each Minimum Viable Change. As an MVC passes through each state in the Validated Change Lifecycle, various portions of the change are validated using one or more Improvement Experiments. Each MVC typically has its own dedicated Improvement Experiment Kanban, placed right next to, or right below, the Change Canvas used to describe the Minimum Viable Change.

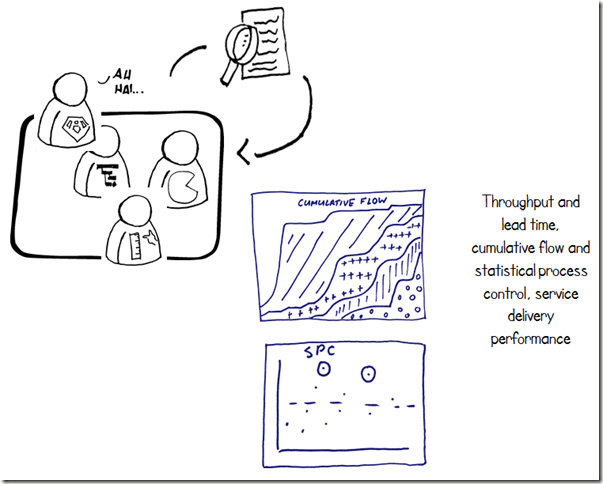

Changes Eventually Need to Be Measured in Terms of Improved Performance, Kanban Provides an Excellent Set of Techniques to Do so

I've already talked previously around how Improvement Experiments are used to validate different aspects of a Minimum Viable Change. As change participants gain experience in lean and agile methods, they start to evaluate Improvement Experiments against performance metrics. Because of its origins within lean, Kanban provides mousedown 20 a rich set of metrics such as leadtime, throughput, and failure intake that can be analyzed using statistical process control or cumulative flow diagrams.

Making this concept real, when a Minimum Viable Change passes through the Verify Performance state, Improvement Experiments can then be evaluated to see if one or more kanban inspired metrics improve. An example of an improvement experiment implemented during the verify performance page could be conducting developer reviews of unfinished requirements documentation on a weekly basis will reduce UAT defect density by at least 30% after one month.

Once the Organization Achieves Sufficient Maturity, Kanban Can Take over As the Change Management Method

Kanban is described as a change management method in its own right, by David J. Anderson and others in the LeanKanban community. This change management approach borrows many techniques and ideas from lead and other bodies of knowledge to enable a viral, and evolutionary change management approach designed to help organizations gradually become more agile over time.

Kanban is designed to provide a gradual way for technology knowledge workers to improve. Knowledge workers start by mapping out their existing delivery process and visualizing this process using a Kanban system, typically manifested as a Kanban card wall.

A combination of methods are used to enable a grassroots, continuous improvement mindset, that in some conditions can virally spread across the organization. These techniques include explicit and visual policies that govern how work is conducted, limiting work in process to enable flow, connecting value delivery through frequent regularly scheduled cadences, and allocating work across visually colored classes of service.

So why not just use Kanban by itself and forget about the Lean Change entirely? It's been my experience that the Kanban method, used in isolation, is not always sufficient to help organizations transform to a more agile state. In some circumstances, helping clients adopt the Kanban method has resulted in amazing performance improvements. In other cases I've seen people attempting to use the method never quite grokking the continuous improvement mindset. Even more unfortunate were the cases where teams were doing well, but management did not adequately support changes being suggested by people who adopted the Kanban method, causing those people to eventually become disgruntled, and abandon the change effort. I have personally experienced a number of Kanban-based agile adoption that stalled because of a lack of patience, existing expertise, or direction.

The Lean Change method enhances Kanban to provide the aspects of a managed change initiative that can help organizations receive the guidance and support they need to be get started with Kanban, or some other continuous improvement method. Eventually, the goal of any agile or lean change initiative is to reduce the need any for an official "managed" change. We want to move from a transformative change mindset to an incremental, evolutionary change mindset. The sign of a true healthy, agile organization is one where improvement is continuous, and driven from employees doing the work.

In A nutshell, Kanban is an ideal method to supports the organization's efforts to continually adapt and improve. Lean Change is there to help with explicit change planning and change coordination when required, whether that change is larger or smaller. Kanban can take over when and where continuous improvement is more appropriate.

Think of Lean Change as a mechanism to make some of the more overt changes required to prepare an organization for Kanban. As change participants get used to working in a lean and agile context, they can start using Kanban to continually improve at their own pace, independent of any "managed change" effort.

For more check out the Lean Change Method: Managing Agile Transformation with Kanban, Kotter, and Lean Startup Thinking .

For more check out the Lean Change Method: Managing Agile Transformation with Kanban, Kotter, and Lean Startup Thinking .

No comments:

Post a Comment